Innovative Technology. Transformative Capabilities.

Tough challenges require robust solutions. Aprecia has multiple technologies, decades of expertise, and a range of specialty services. We can redefine medicine … together.

Your Solution Has Never Been So Suite

Whether you need assistance in navigating early-stage development or managing an existing product’s lifecycle, Aprecia’s expert team and unique suite of advanced technologies in precision formulation, oral drug delivery forms, and 3DP production can meet your needs.

Drug Delivery Forms

Our pioneering 3DP manufacturing process offers flexible oral dosage forms with tailored functionalities and a range of API compatibility.

Flexible Oral Administration

Traditional Tablets

Sublingual/Buccal Tablets

Orodispersible Tablets

Embedded Functionality

Taste Masking

Modified Release

Enhanced Bioavailability

Broad API Compatibility

High Dose

Ultra-Low Dose

Fixed-Dose Combos

High-Potent Capabilities

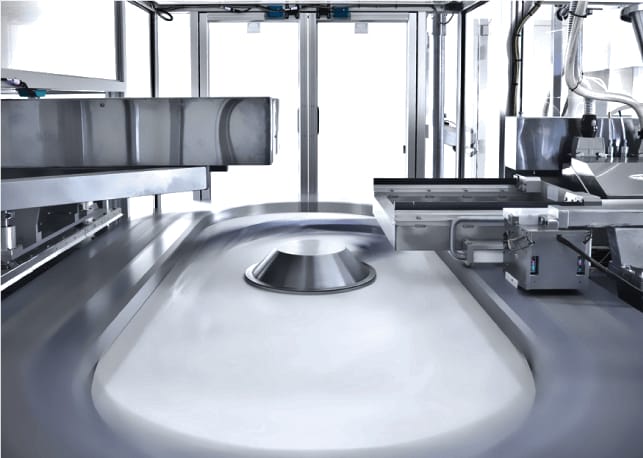

3DP PRODUCTION TECHNOLOGY PLATFORMS

Aprecia offers distinct, patent-protected 3DP production platforms—our Open Bed 3DP-Tablet Forming Platform and our In Blister 3DP-Tablet Production Platform.

For Feasibility and Early Formulation

Our 3DP production platforms increase R&D throughput by enabling fast and efficient feasibility assessments and rapid prototyping.

For Clinical Trial and Low Volume Market Supply

Each platform can produce clinical supplies suitable for Phase I-III trials.

For Commercial-Scale Production

Our Open Bed Production Platform is commercial ready, with breakthrough binder jetting innovations that can deliver capacity at scale.

In Blister 3DP-Tablet Production System

Comprehensive CMC Support

At Aprecia, we provide unparalleled CMC support. Our team of seasoned experts offers in-depth guidance on quality and regulatory compliance from initial development through commercialization, ensuring your products meet the highest industry standards worldwide.

Our CMC services encompass a range of activities, including:

- Raw Materials We assist in the selection and testing of raw materials to ensure they meet the required specifications and are suitable for your product’s formulation.

- Analytical Methods Our team specializes in the development and validation of analytical methods, crucial for accurately monitoring product attributes.

- Stability Testing We conduct comprehensive stability testing to evaluate how your product withstands various environmental conditions over time, ensuring its safety and efficacy until the end of its shelf life.

- Physicochemical Properties Determining the physicochemical properties of your product is essential. Our experts carry out detailed analyses to understand these properties, which inform formulation and manufacturing decisions.

- Manufacturing We define best practices and establish scalable manufacturing methods to facilitate large-scale production while maintaining product quality and integrity.

- Quality Control Implementing stringent quality control measures is paramount. We develop and oversee protocols to ensure that each batch of your product conforms to predefined standards, minimizing risks and maintaining consistency.